Mine is superior braking performance can make the hoist motor smooth, safe and reliable braking operation, avoid severe mechanical wear, prevent larger mechanical shock, reduce maintenance workload, mechanical part extending the service life of the ascending machinery. Mine hoisting system automation, improve system performance, and improve the requirements, such as lifting equipment upgrade ability of mine ac high voltage motor braking requirements more and more is also high. Mechanism of promoting traditional mine still, almost all adopt dynamic braking or low frequency generator braking way, way of power braking can only solve the problem of braking, can't better solve the problem of crawling, low-frequency generator can better solve the above problems, the whole control system is more complex, use equipment also is more, cause the inconvenience to the system maintenance and overhaul.

A coal mining history has been more than 30 years, especially with the national economy changing from planned economy to market economy gradually, the east mine to adapt to market economy rule, to meet the needs of reform and opening up, gradually get out of the difficulty the economy through increased investment from the enterprise transformation, all staff work together, now the east mine industry, not only economic benefits, the worker income on a new step, and the mining face great changes have taken place. Successfully out of the road of the development growth of the small coal mine had been province coal group company and national coal.

General inverter can output at low frequency, but the system modeling and design is aimed at a low voltage motor, the output frequency and always existed certain proportion relationship between the output voltage and the direct use of low-frequency braking and crawling in the mine motor, also will cause started low frequency input as the inverter output voltage is too high, the braking torque is too big, then the motor's power state feedback back to the inverter power is bigger also, the inverter braking resistor choose not too appropriate, will also cause overvoltage dangerous frequency converter, use for a long time, will cause the inverter dc capacitance bridge burned, crawl low frequency at the same time, its braking, give attention to two or more things crawl will lead to the motor torque is small.

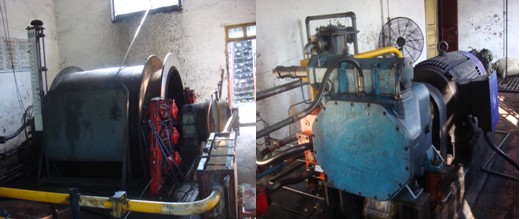

Site promotion winding machine

Application process requirement on site

Mine hoist is the main equipment for underground mine transport, it is to use certain equipment along the shaft out of the ore and waste rock, lift personnel, materials, equipment, transportation, etc. The winch can be driven by the main oil pump, control of hoist speed is controlled by the main oil pump. Normal work the main oil pump are in operation, power frequency yes keep the pipeline pressure (to drive hoist), when the winch does not work, the main oil pump can run in low speed, prevent once work in a short period of time when starting the main oil pump to industrial frequency operation, maintain the main oil pump pressure. So don't work, 35 hz inverter can keep running, achieve energy saving effect.

Solution:

1, the use of fconverter speed control, to solve the speed of the winch working and not working.

2, plus a braking unit (when the winch to devolve winch also began to grow fast, result in higher inverter dc bus voltage start, a motor for inverter power state)

Electrical wiring diagram, parameters setup:

F0.11=1 Terminal block control

F0.13=50 Acceleration time 1

F0.14=50 Deceleration time 1

F0.03=6 Multi-speed operation setting

E1.01=70% 1-stage speed setting 1X

E1.02=100% 2-stage speed setting 2X

E1.21=1 1 stage ac/deceleration time

E1.23=1 2 stage ac/deceleration time

F7.08=15 Acceleration time 2

F7.09=25 Deceleration time 2

The working condition of the inverter of daily maintenance and matters needing attention:

1. Pay attention to the dust, water, metal powder immersion, regularly cleaned.

2. To avoid vibration.

3. The environment temperature should be kept below 40 degrees Celsius.